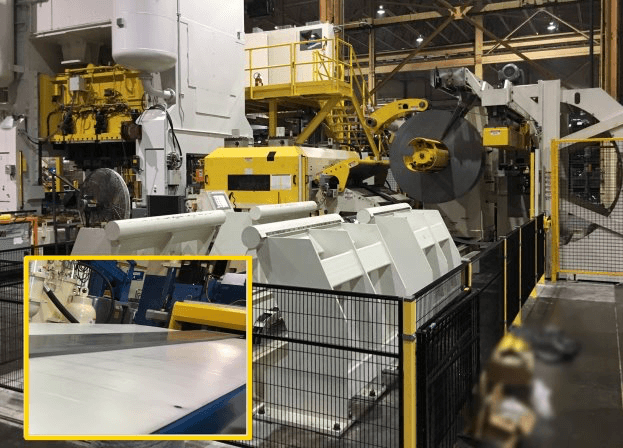

COE Press Equipment has announced the installation of its “Fineblanking Edition” HD straightener, coil reel with HD hold-down arm, and “alligator” style peeler threader at Hoerbiger Fineblanking (Waterloo, Ontario), a manufacturer of components and systems for gear shifting and declutching drive trains for passenger cars, trucks, and offroad vehicles. COE’s Fineblanking Edition straighteners providethe necessary roll force delivery and rigidity required to achieve the flatness and tolerance required for producing near net shape blanked parts.

In addition to the COE 5-in. x 36-in. Fineblanking Edition power straightener, the equipment includes a COE 36-in. x 30-in. threading table offering hands-free threading capability, and a 20,000-lb. x 36-in. coil reel with coil clock spring guard including a motorized endwheel for effective coil containment. It also features centralized controls for the straightener and feeder.

The equipment is capable of processing high strength steels up to 110,000 PSI yield at thicknesses from 0.078-in. to .630-in depending upon the width of the material. It can achieve a payoff rate up to 80 FPM.

This is the largest fineblanking equipment to date that COE has shipped and its third installation for Canadian fineblanking companies. COE also provided installation, startup and training assistance.

COE Press Equipment is a leading provider of coil processing technology, providing comprehensive solutions for complete integrated lines as well as stand-alone roll feeds, straighteners, and reels. It offers the heaviest and widest coil feeding systems available for the global metalstamping industry today. COE services a wide variety of industries including automotive, appliance, lighting, metal processing, housewares, lawn and garden, contract stampers, tool and die builders, and many others.