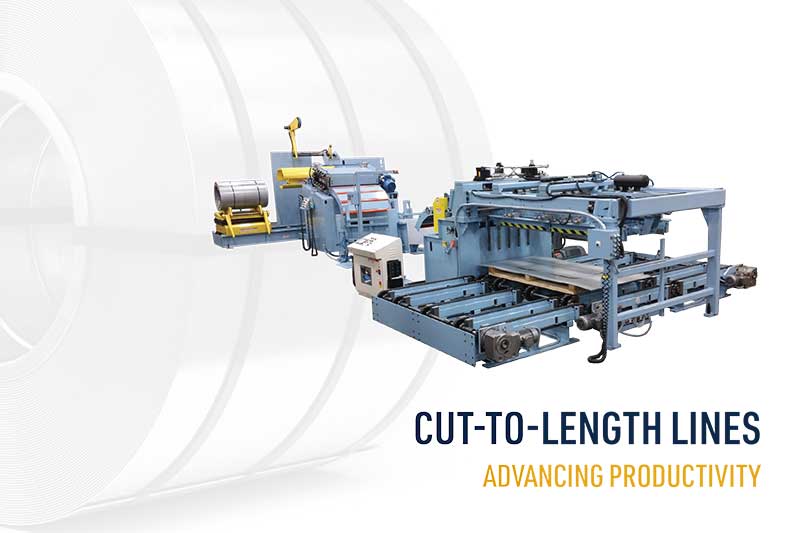

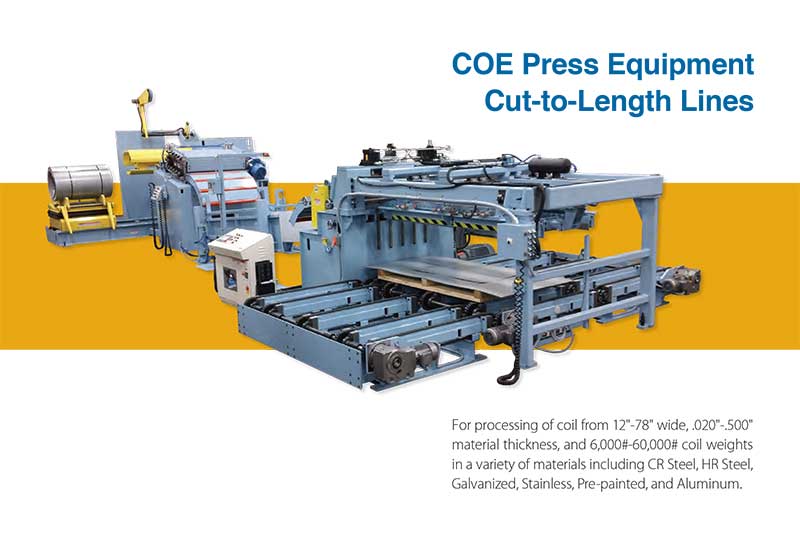

A cut-to-length CTL coil line processes metal coil rolls by uncoiling, straightening, shearing to length and stacking of sheet metal blanks. These lines provide automation that ensures accurate feeding, shearing, and flattening for a variety of industries. Bringing these lines into your fabricating operations can eliminate blank processing fees and help you gain a competitive edge by taking control of your inventory and production schedules with your own blanking coil line. In-house CTL capability gives you flexibility to run blanks in the sizes you need when you need them.

COE cut-to-length CTL coil lines are configured from our standard and performance-proven feeds, straighteners and reels coupled with COE shear and stacking solutions to deliver a complete integrated blanking coil line that is right-sized to your particular needs. Whether you’re a general fabricator, OEM or stamper, COE’s cut-to-length CTL lines can be built to your specific needs. You get proven designs manufactured with attention to detail and backed by the COE Assurance 24/7/365 service advantage.

| Opportunities | Potential Gains |

|---|---|

| Outside Cost Savings | Eliminate $20 to 50/ton in processing fees |

| Transportation Savings | Eliminate $1.50 to $2.00/mile in trucking fees |

| Inventory Reduction | Reduce work-in-progress (WIP) and carrying costs |

| Streamline Processes | Apply just-in-time (JIT) to blanking operations |

| Improved Quality | Easily detect and contain material defects |

| Reduce Scrap | Optimize materials usage by blanking to size |

| Optimize Floor Space | Use floor space for value-added operations |

An in-house CTL line lets you run the blanks you need when you need them.

DOWNLOAD BROCHURE

From light to heavy gauge applications, COE can develop the right CTL solution to fit your unique metal processing needs.

DOWNLOAD BROCHURE

The cost savings of bringing cut-to-length operations in-house can be significant.

DOWNLOAD BROCHURE