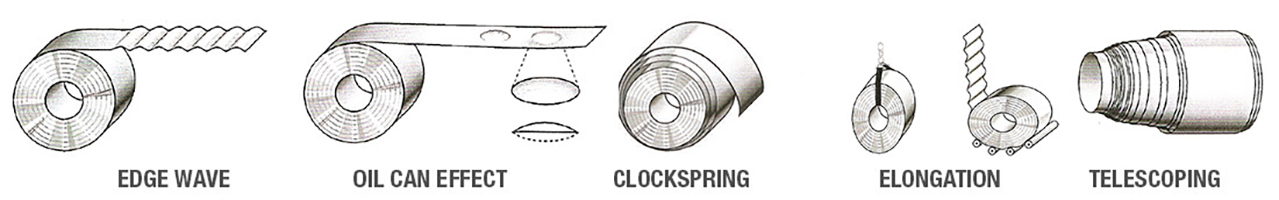

Edge wave – This anomaly is also referred to as scalloped edges and is another condition that can be detrimental to coil processing efficiency and part quality. If it occurs at the coil handling, straightening, and feeding process it is most likely the result of excessive pinch roll pressure or excessively stressed rolls, which deflect in the center and deform the edges of the material.

Oil can effect – This condition usually appears after the blanking operation. The material is “dished” so that the center of the material is stretched more than the edges. If rolled, the bump will simply transfer to the other side or pop back and forth like an oil can. This condition results at initial coil production and is often worsened by subsequent processing. Conventional coil handling equipment does not provide a remedy for this situation.

Coil Clockspring – This is the tendency for the outer coil wraps to separate from one another in an uncontrolled manner and spread outward around the coil diameter. In effect, the coil begins to grow. Excessive clockspring can represent serious danger to personnel. Under moderate conditions, unrolling from a cradle can slow the tendency toward clockspring as the weight of the coil rests on each outer wrap. Reels can be equipped with coil hold downs or restrictors to minimize this problem. And, under the most severe conditions, special heavy duty restrictors can be specified for reels and cradles. Hands-free threading capability with a peeler/threader/hold down system assures efficient coil threading and operator safety.

Telescoping Coils – This is the tendency for individual wraps or groups of wraps to move sideways resulting in damage of material edges and significant operating problems in maintaining alignment and smooth material flow. Diligence at the coil processing stage with proper tensioning and alignment, resulting in evenly wound coils, is the best cure.

Elongation of Coils – Elongation of coils Coil stock has become well established within the metalworking industry over the past few decades. Thin or loosely wound coils tend to elongate in the handling process, especially when provided in heavier weights. These coils are not suitable for cradle type uncoiling and can, instead, be handled with coil cars or coil slings to load the roll on reels.