One of the primary decisions that must be made when selecting a coil feed system is choosing the correct coil weight capacity. The run time between coil changes factored with the amount of time it takes for a coil change will help you to determine the optimum coil weight for your operation. Although the maximum coil weight selected should be within the capacity of the existing cranes or lift trucks, sometimes it makes sense to upgrade these.

Generally speaking, by maximizing coil weight, production time lost due to coil changes can be minimized.

Equipment for handling smaller coils will cost less and the coils are a lot easier to handle.

Although width is a major factor in determining coil weight, other generalizations can be made regarding how quickly a coil will be depleted. Material thickness is another important consideration.

For a given coil size, the thinner the material the more linear feet it contains, resulting in longer run times. In general, if you run thin material, short progressions or slow speed, the run time between coil changes will be longer, in which case smaller coil weights make sense. Equipment for handling smaller coils will cost less and the coils will be a lot easier to handle. On the other hand, if you use thick material, run long progressions, or high speeds, the coils will be consumed at a much faster rate. Larger coil weights and the proper equipment to change coils and thread quickly will be advantageous in this case.

The run time between coils must be considered in combination with the amount of time it will take to load and thread a new coil. Generally, thinner gauge, low strength material is more pliable and has less stored energy in the coil. Threading is typically easier, faster, and requires less equipment than with heavy gauge materials, so the effect of larger coils of thin gauge/low strength materials on overall efficiency is not as great even if coil changes must be made more frequently.

Unless equipment is properly outfitted when working with thicker gauge or higher strength materials, assume that it will take longer to thread a new coil as well as being more dangerous . In this case, larger coil weight capacity and the options required to safely and quickly thread thick material will cost much more initially, but justified by the increased productivity and safety.

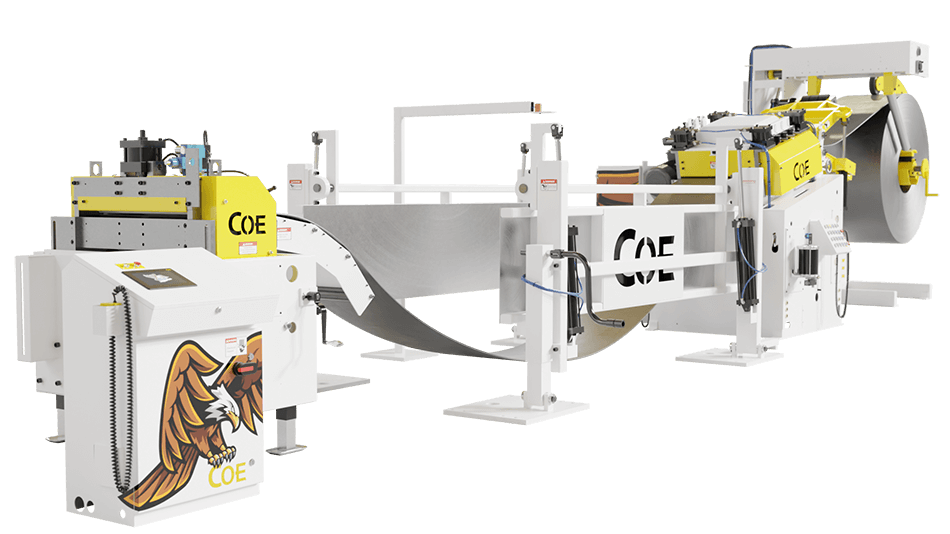

Thicker gauge materials typically require additional equipment options to ensure safe and quick threading of the coil.

Although often of a thinner gauge, high strength steels can telescope and clockspring , requiring effective coil containment equipment.

However, these generalizations do not apply to the advanced high strength steels that are increasingly entering the market as manufacturers try to lighten overall weight of their products without sacrificing strength. These materials are a combination of thin gauge, yet high strength — so there is a lot of energy stored in the coil and, once unbanded, they are prone to clockspring. These advanced materials require the same investment in equipment as thick gauge/high strength materials. Additional features required may include a heavy-duty hold-down with a motorized endwheel for effective coil threading and rewind, as well as coil guides for accurate coil placement and containment of telescoping.

If an application calls for .250″ thick by 24″ wide steel with a 36″ feed length running at 30 strokes per minute, a 10,000 lb. coil with a 20″ I.D. will yield about 163 parts and the run time between coil changes will only be about 5 1/2 minutes. If it takes 10 minutes to load and thread a new coil then the net yield will be roughly 630 parts per hour if we ignore time for breaks, set up, maintenance and repairs.

If the coil weight is doubled to 20,000 lbs., a coil will yield about 327 parts. The run time between coil changes would increase to nearly 11 minutes and the net yield will increase by 48% to about 935 parts per hour. In this case the additional cost of equipment to run the bigger coils would be easily justified by the increased productivity.

In another application using .032″ thick material at 24″ wide with a 20″ feed length running at 30 SPM a 10,000 lb. coil would yield 2300 parts and run for roughly 77 minutes between coil changes. Assuming a time of 5 minutes for coil change, the net yield would be about 1690 parts per hour.

If the coil weight is increased to 20,000 lbs. a coil will yield about 4600 parts and the run time will be 153 minutes. Factoring in the coil change time, the gain would only be about 3%, for an output of 1740 parts per hour. With this small of an improvement, it is difficult to justify the increased cost of equipment required to handle the larger coils. In fact, in this case you might want to look at even smaller coils because the cost savings for lighter equipment may more than offset any loss in efficiency.

In order to optimize your equipment usage and output, it is smart to look at your requirements and then work with a seasoned supplier who can help you calculate productivity as compared against the cost of the equipment investment to ensure you get the optimal solution for your needs.

COE’s coil handling equipment comes in a variety of sizes and COE’s technical team can help determine the best solution for your application.