COE Press Equipment was recently featured in The Fabricator, where R&D Manager Bruce Grant discussed how our heavy-duty straighteners are helping manufacturers meet the demands of processing advanced high-strength steel (AHSS).

As AHSS becomes more common in the automotive and appliance industries—driven by the need for lightweight, fuel-efficient vehicles—manufacturers face new challenges with material formability and flatness. Coil-set, crossbow, and tight tolerance requirements can slow down production and increase tool wear.

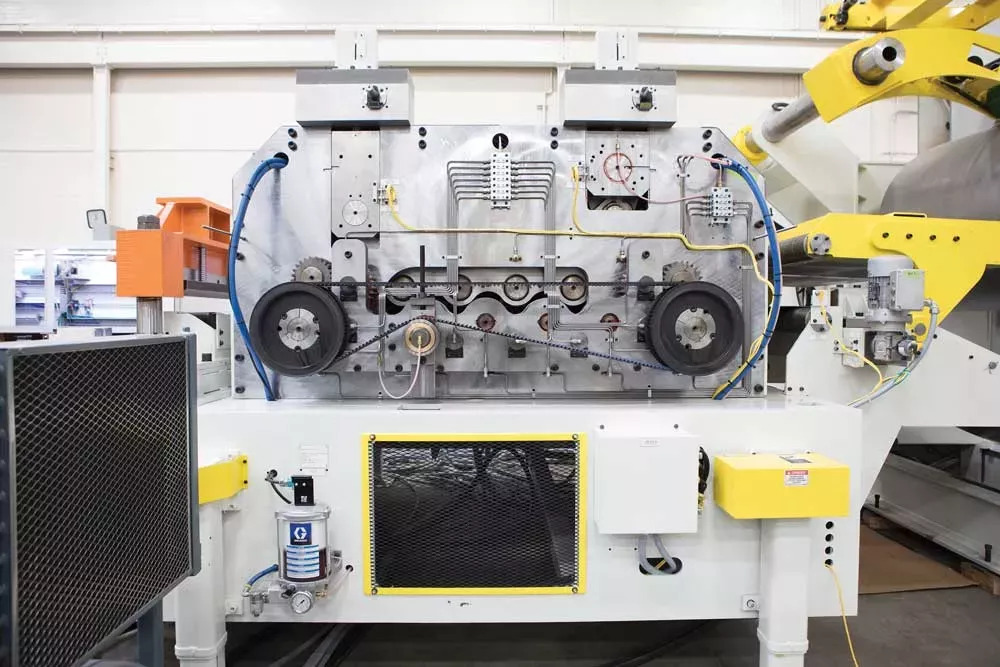

Bruce’s article, “When Flat Is Where It’s At,” highlights how traditional feed line equipment struggles to deliver the roll force and structural rigidity needed to flatten today’s stronger, more complex materials. That’s where COE’s latest technology comes in.

Small-diameter precision work rolls

Reinforced frames and backup mechanisms

Tight roll spacing and deeper penetration

Improved gear trains and servo-based release functions

Two customers featured in the article—Nahanni Steel Products and UTIL—implemented our SpaceMaster® and Fineblanking Edition lines to tackle problems like crossbow, inconsistent flatness, and safety concerns. Since installation, both companies have seen improvements in throughput, material handling safety, and output quality.

To read the full story, check it out on The Fabricator’s website under the title “When Flat Is Where It’s At”.