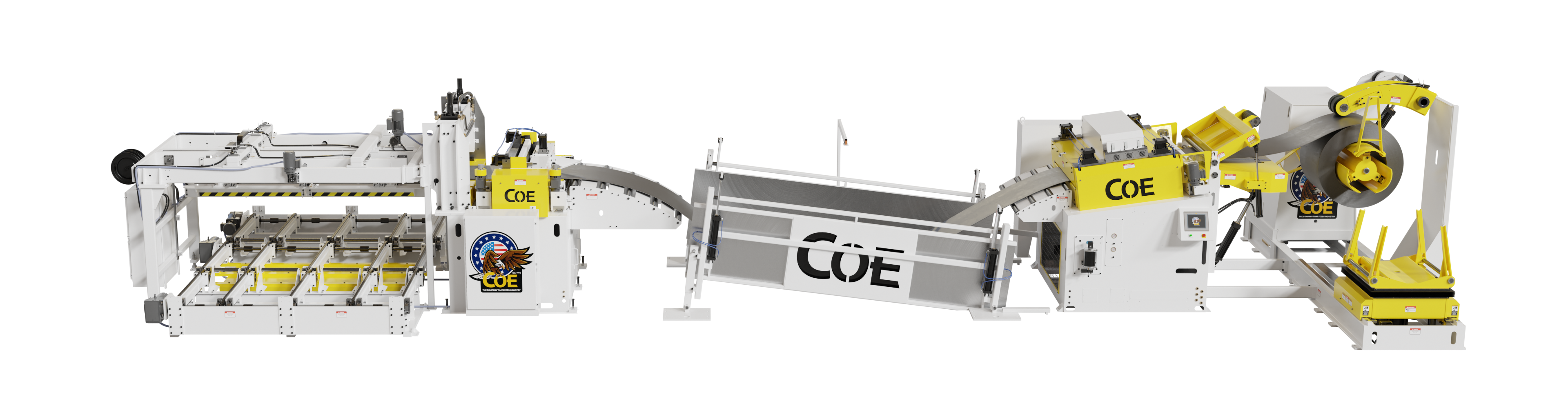

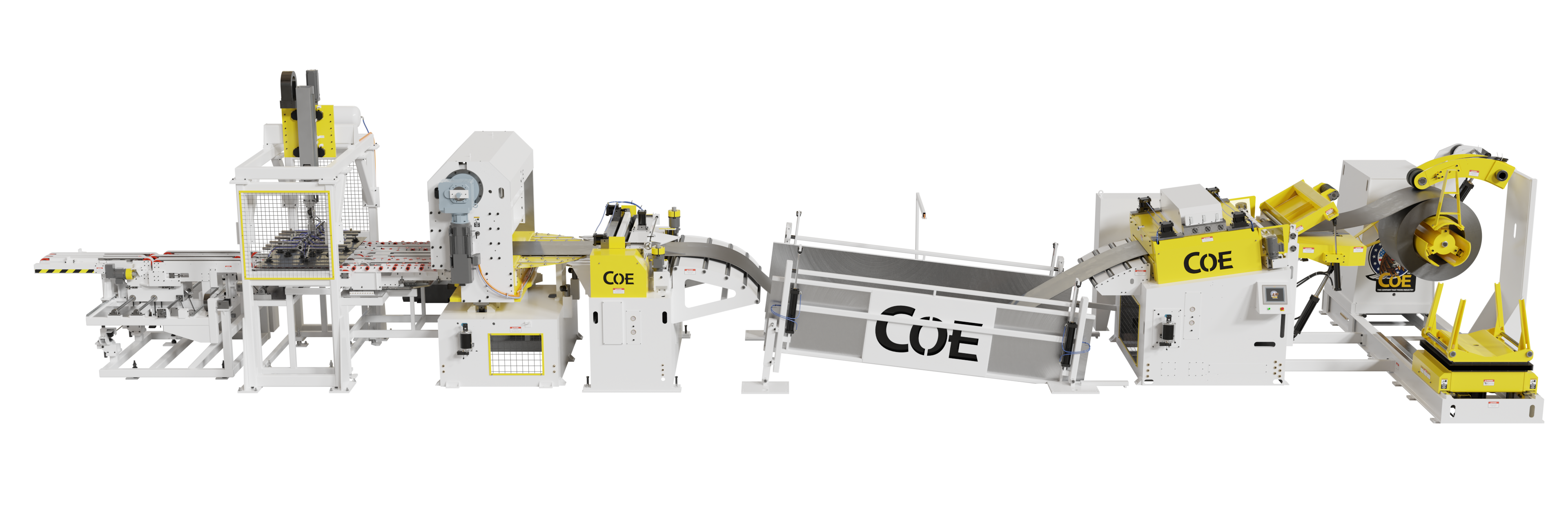

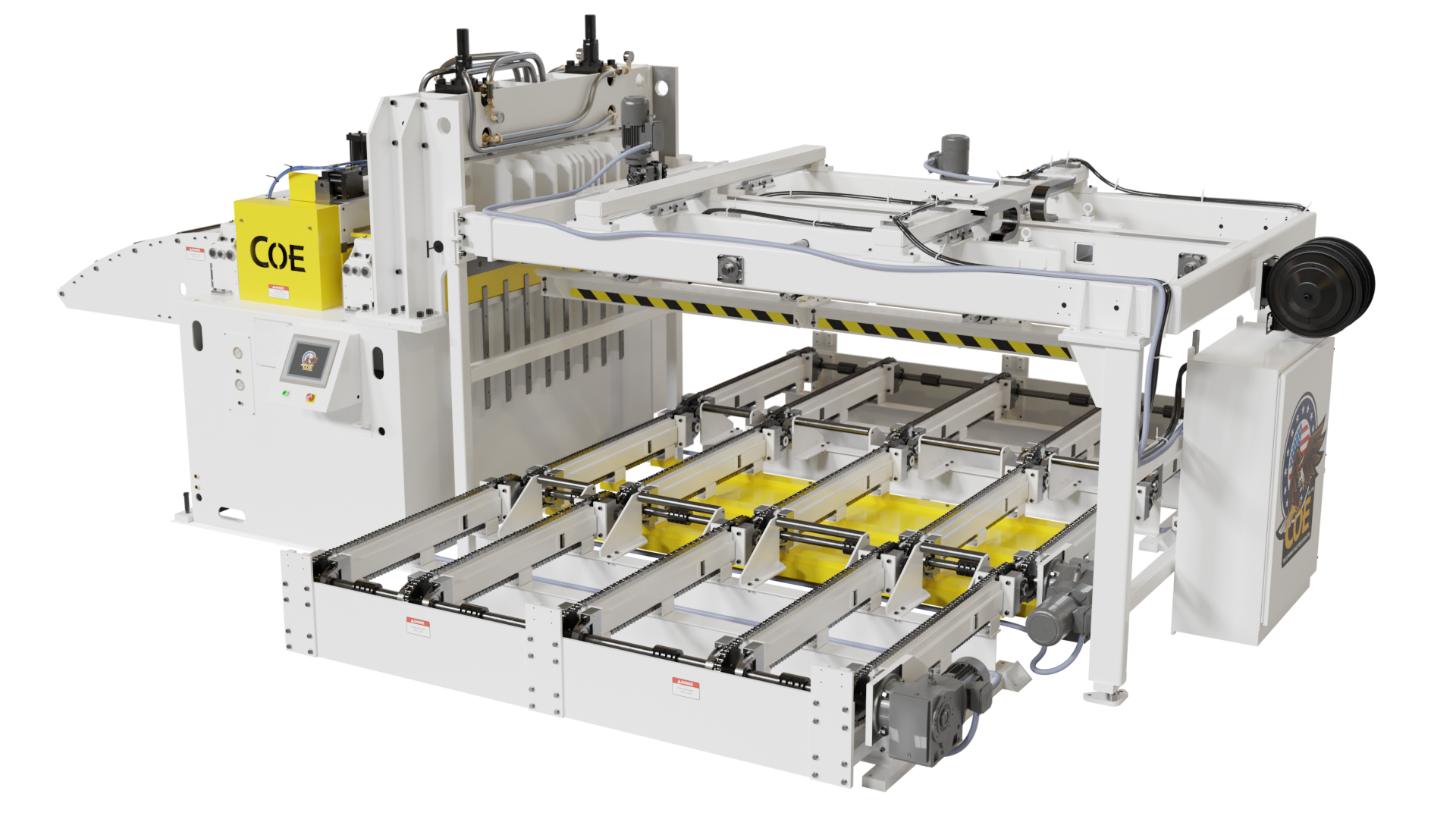

On behalf of all of us at COE Press Equipment, thank you for visiting our booth at NATM in Nashville. We’re committed to supporting trailer manufacturers with innovative blanking and cut-to-length lines tailored to meet the demands of JIT manufacturing. Our solutions are designed to enhance control, streamline production, and maximize your ROI. Whether you’re focused on efficient material handling, reducing downtime, or optimizing output, COE’s comprehensive solutions are built to drive your business forward. We look forward to helping you achieve your manufacturing goals.

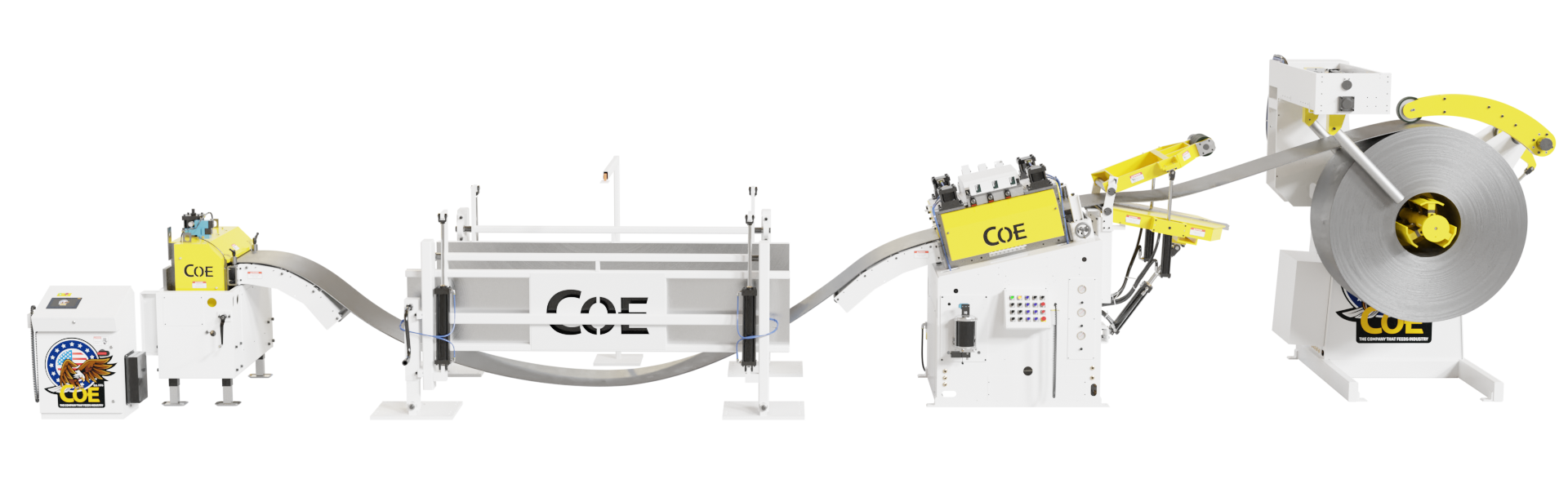

With COE Press’s advanced blanking line solutions, manufacturers can bring blanking in-house, eliminating costly outsourcing fees for immediate savings. COE’s equipment enables greater control over production schedules, reducing delays and enhancing operational efficiency. This one-time investment provides substantial ROI as ongoing savings quickly offset the initial costs, making COE Press a valuable partner in driving profitability. Additionally, COE’s blanking line allows companies to unlock new revenue streams by offering blanking services to other manufacturers, further boosting ROI and business growth.

Have questions or need more information? Our team is here to help!

Follow us on social media to stay informed about our latest updates and industry trends.

Your insights are important to us. Please take a moment to share your experience at NATM and let us know how we can better serve you. Provide Feedback

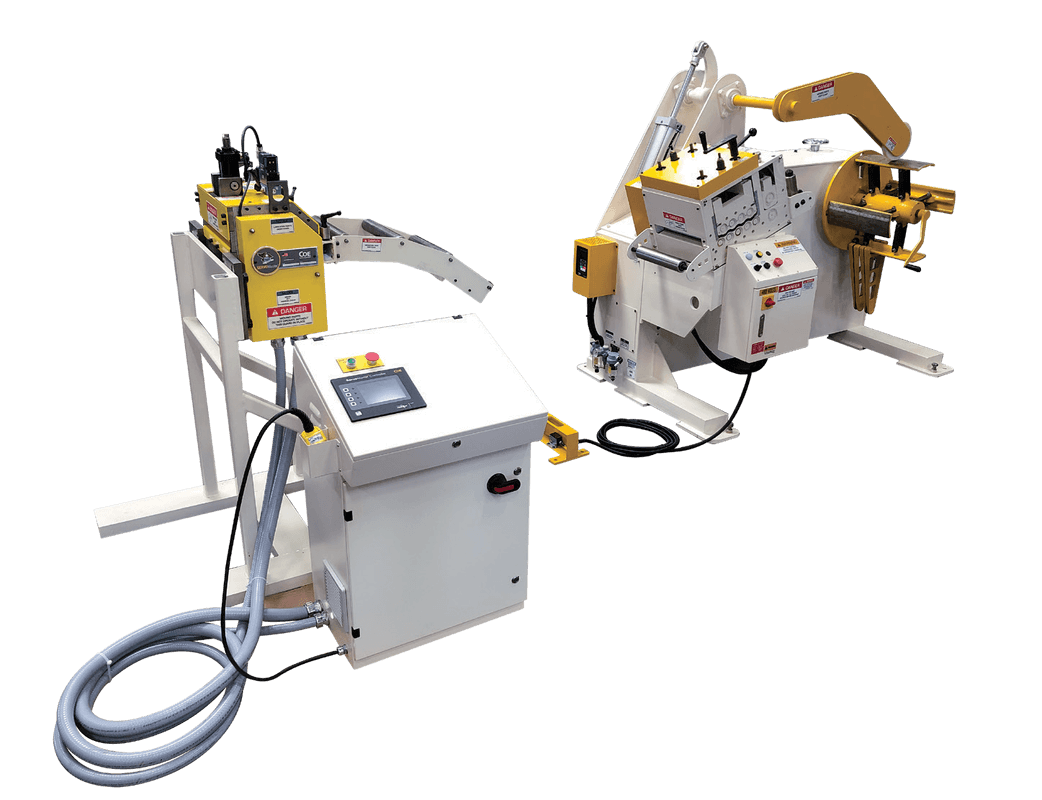

Capital equipment investments are nothing to be taken lightly. So, it’s important to get the best performance and service life you can from your equipment. But, sometimes new materials and production requirements can challenge equipment. COE provides a number of options that can help improve the productivity of your existing coil feeding line.

COE Press Equipment stocks and maintains a wide range of standard replacement and repair parts for our complete product line – with over half our orders shipped within 24 hours. For special parts, COE’s vertically integrated manufacturing capability allows us to manufacture on site to produce the parts you require efficiently and cost-effectively.

And, our unique warranty provides great coverage that you can count on.

Air Feed and Legacy Parts

Looking for replacement parts for our historical line of air feeds? Use the links below to download PDFs to help you identify your air feed as well as the parts you’d like to order. Then, just call us with the identification numbers so we can provide price and availability.

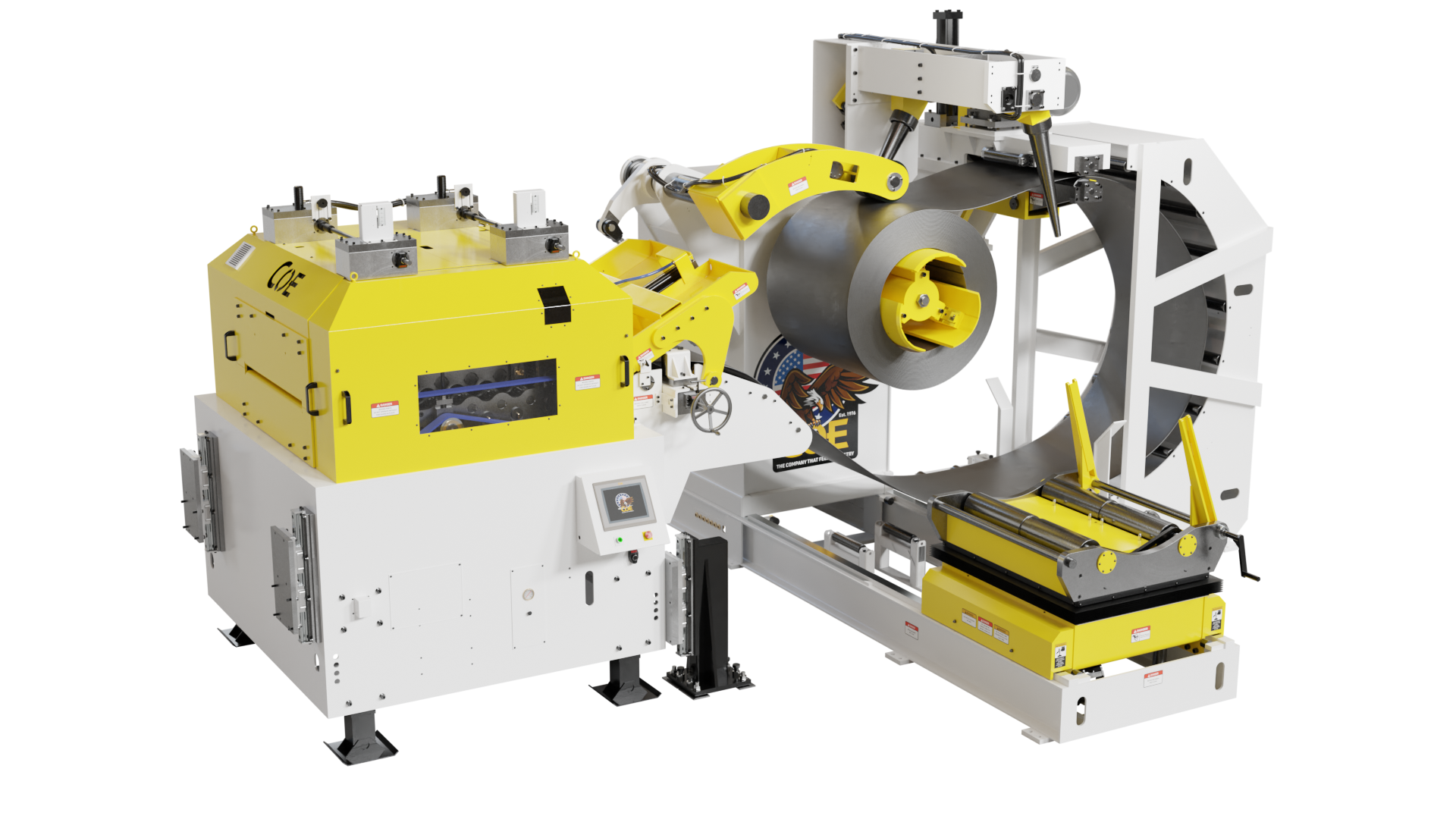

In recent years, COE has made a strategic move toward modular coil feed line products based upon standard designs. This change has reduced the number of components required, reducing the number of welds and streamlining assembly. This has enabled the company to increase the reliability and simplify the maintenance of the coil processing equipment, as well as accommodate reconfiguring machines as customer needs change.

“We believe that COE has always been recognized for producing robust machines,” commented President, Reid Coe, “but with our new designs, we see even more reliability with fewer parts required for repairs, enabling us to confidently offer this unique warranty.”

All coil feed systems manufactured new by COE Press Equipment are delivered to our customers with the additional assurance of our Industry Leading “5-4-3” Warranty on material and workmanship as stated below from date of shipment. COE Press Equipment utilized suppliers and manufacturers of high quality mechanical and electrical components. This overall dedication to quality assures long term performance of our products and provides the highest return on the capital investments for our customers. Our Industry-Leading “5-4-3” Warranty provide unequaled assurance that COE Press Equipment products will be supported in our customer’s facilities. In the event that a customer has a problem outside of normal business hours, our 24 Hour Technical Service Hotline provides immediate support and reduced downtime.

Uncoiling, straightening and feeding material to the press are certainly the basics of coil processing. However, there is a lot of engineering and nuance behind each of these processes and the equipment that performs them. These resources are designed to quickly provide you understanding of various aspects of coil processing and the equipment choices that are available, all aimed at helping you in your role.