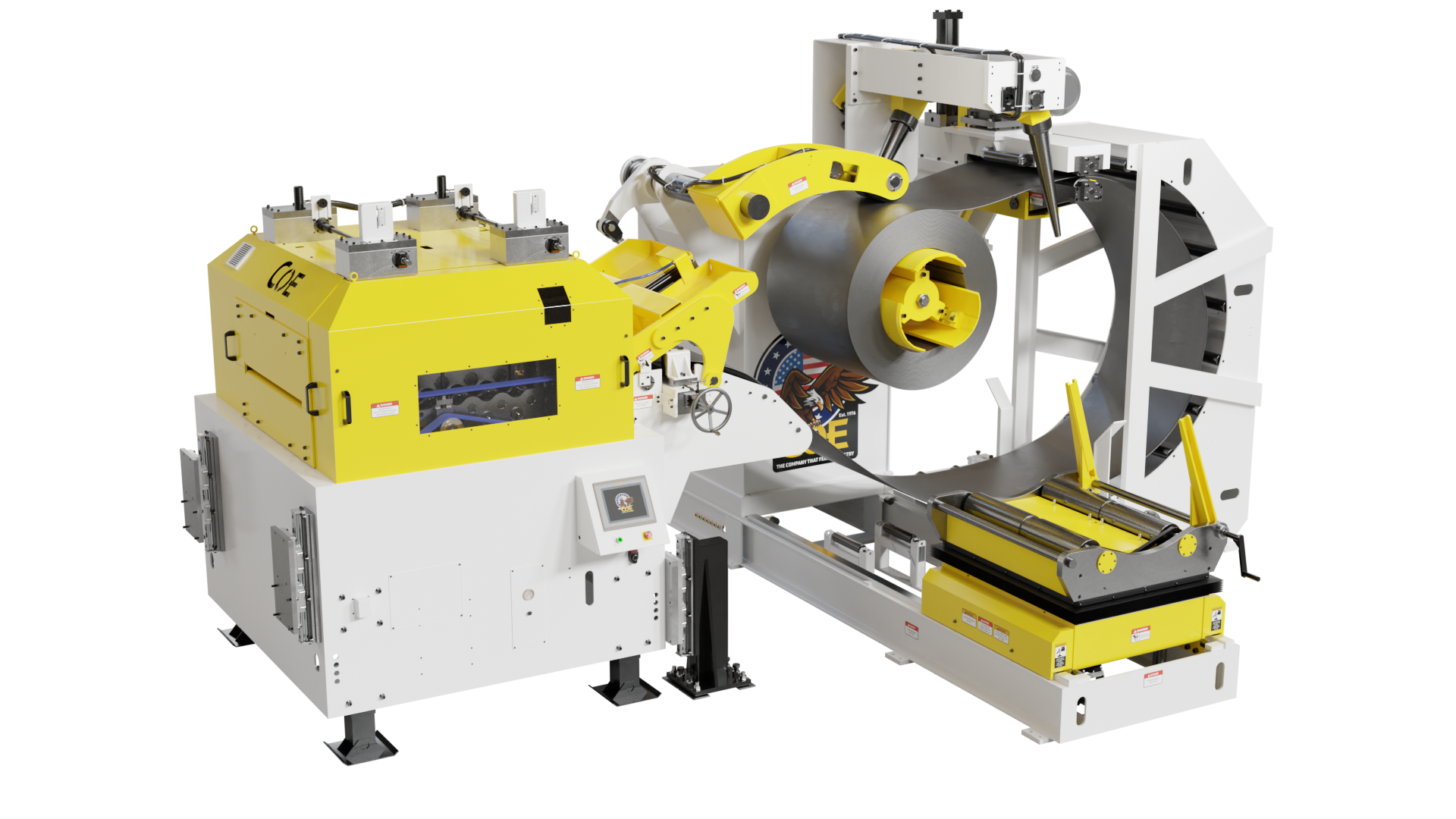

COE Press Equipment has shipped and installed a SpaceMaster Series 3 compact coil line to Ameristar Manufacturing, a full-service metal fabricator based in Mankato, Minnesota. This all-in-one compact coil line integrates unwinding, straightening, and feeding functions in a single, space-efficient system — ideal for pressrooms with limited floor space.

Unlike traditional feed lines that can require over 30 sq-ft., the SpaceMaster Series 3 fits within just 15.33 sq-ft., helping Ameristar optimize valuable production space without sacrificing performance.

Compact Coil Line Capabilities

- Material Thickness: 0.010” to 0.187”

- Coil Width: Up to 20”

- Coil Weight: Up to 11,000 lbs.

- Material Types: CRS, HRS, stainless steel, aluminum

- Line Speed: Up to 60 strokes per minute (SPM)

Built-In Features for Efficient Operation

The system includes standard features that enhance coil containment, safety, and setup speed:

- Powered coil guides

- Hydraulic hold-down with motorized endwheel

- Pivoting peeler-debender for efficient threading

These features support hands-free coil threading and precise strip feeding, minimizing downtime and operator intervention.

Compact Design. Full Performance.

With its minimal footprint and full-featured capability, the SpaceMaster Series 3 is ideal for high-mix, low-volume operations, job shops, and any manufacturer needing to maximize floor space without compromising on coil processing performance.

To explore whether a compact coil line is right for your pressroom, contact COE’s sales team today.

Published August 27, 2021